Packem Umasree's

Larger Vision of Sustainability

As a packaging manufacturer, Packem Umasree takes responsibility for addressing the challenges of the industry and develops technological solutions that reimagine its relationship with the environment. The company has undertaken multiple initiatives with the goal of waste elimination and environment-nurturing development, under the approach called WEEN.

The packaging of the future is 100% made from renewable or recycled materials, produced using renewable energy, and after fulfilling its purpose, returns to recycling to be renewed.

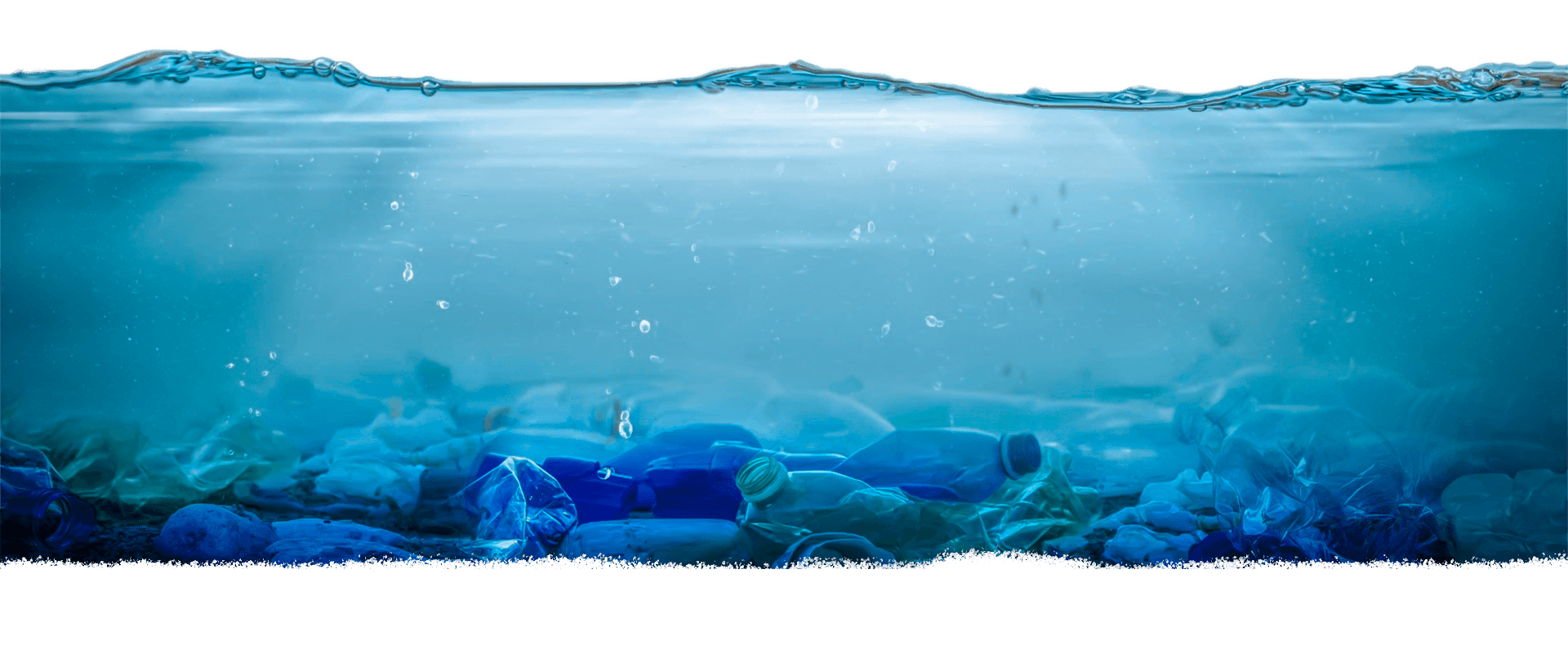

Reimagining Plastic Waste Management

We believe that the first step towards transformation is to dream of a tomorrow—one that is better and brighter than today. While the problem looks overwhelming, taking committed steps in the right direction brings in unexpected change. The plastic industry needs to rethink its approach, and as active participants in the production chain, we lead the solution. With economic incentives aligned to promote products with the necessary technical specifications and recycled material sources (PCR), the economic chain is established and fostered to build the necessary supply, effectively addressing environmental concerns.

Reimagining End of Waste

Reimagining End of Waste

Our company is committed to achieving a sustainable circular economy, and we take a quantum leap towards this goal with our innovative approach. It begins with collecting used PET bottles and bags, converting them into flakes, and transforming the recycled material into sustainable FIBC bags. These bags are sold in both domestic and international markets as a sustainable packaging product. By using rPET FIBC bags, we significantly reduce CO₂ emissions and contribute to a cleaner, healthier planet. We invite everyone to join us in making a positive impact on the environment and creating a more sustainable future.

One of the major outcomes of sustainable FIBC production is the reduction of new plastic waste. At the same time, the used PET bottle collection process is incentivized and professionally monitored, resulting in optimum results. This saves significant landfill space in India.

Packem Umasree’s sustainable FIBC production supports ‘Make in India’, creating jobs, fostering local skills, and driving self-reliant, high-quality manufacturing.